详细介绍

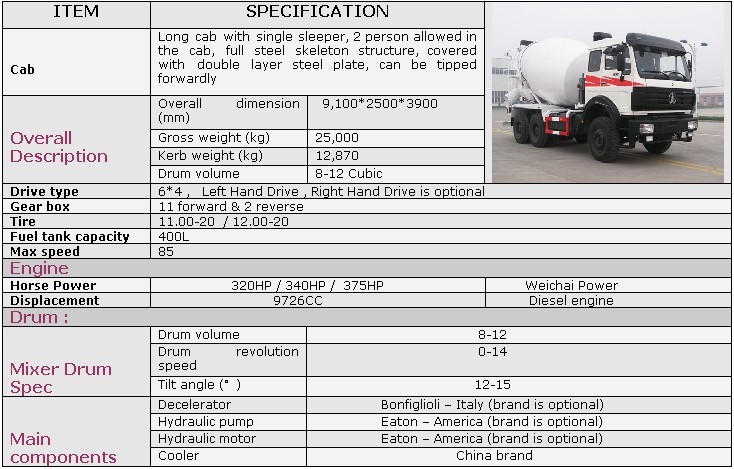

NORTH BENZ Concrete truck

|

Chassis |

||||||||

|

OEM / ODM Different Concrete Mixer can be equipped with different chassis from DFAC, FAW, CNHTC, JAC, FOTON,ShangQi-SHACMAN, ISUZU, HuaLing, North Benz.- BEIBEN |

||||||||

|

More technical specification about the wheel base PLS contact with us. |

||||||||

|

The drum can be selected from 3m3, 4m3, 5m3, 6m3, 7m3, 8m3, 9m3, 10m3, 11m3, 12m3. |

||||||||

|

|

||||||||

|

Equipment |

|

Material And Technology |

||||||

|

Italy ARK motor |

|

Excellent National standard 16 M steel 5mm boom 6mm. |

||||||

|

Italy hydraulic pressure oil pump |

|

Automatic submerged arc welding. |

||||||

|

TOP68 Reducer |

|

Cold Forming Technology. |

||||||

|

German AKG radiator |

|

Hyperboloid stirring blades. |

||||||

|

Drum Technicle data |

||||||||

|

Drum Transmission Capacity |

3000 L |

4000 L |

5000 L |

6000 L |

7000 L |

8000 L |

9000 L |

|

|

Drum Capacity |

4700 L |

6000 L |

8000 L |

9770 L |

10447 L |

13400 L |

14900 L |

|

|

Charge Ratio |

0.67 |

0.67 |

0.64 |

0.63 |

0.67 |

0.615 |

0.6 |

|

|

Charging Speed |

≥3M3/ min |

≥3M3/ min |

≥3M3/ min |

≥3M3/ min |

≥3M3/ min |

≥3M3/ min |

≥3M3/ min |

|

|

Discharge Speed |

≥2M3/ min |

≥2M3/ min |

≥2M3/ min |

≥2M3/ min |

≥2M3/ min |

≥2M3/ min |

≥2M3/ min |

|

|

Discharge Residual Rate |

≤0.8 % |

≤0.8 % |

≤0.8 % |

≤0.8 % |

≤0.8 % |

≤0.8 % |

≤0.8 % |

|

|

Drum Rotation Speed |

0~16 r/min |

0~16 r/min |

0~16 r/min |

0~16 r/min |

0~16 r/min |

0~16 r/min |

0~16 r/min |

|

|

Filling Height |

1.92 M |

2.2 M |

2.3 M |

2.4 M |

2.5 M |

2.55 M |

2.6 M |

|

|

Discharging Minimum Height |

0.87 M |

1.13 M |

1.1 M |

1.13 M |

1.15 M |

1.2 M |

1.2 M |

|

|

Axes Angel |

14±0.5 |

14±0.5 |

14±0.5 |

14±0.5 |

14±0.5 |

14±0.5 |

12±0.5 |

|

|

Overall Dimension |

3.9*1.8*2 |

4*1.95*2.2 |

4.8*2.3*2.15 |

5.2*2.1*2.4 |

4.4*2.1*2.47 |

5.2*2.2*2.6 |

5.4*2.3*2.65 |

|

|

Oil Tank Capacity |

180 L |

180 L |

220 L |

260 L |

280 L |

280 L |

300 L |

|

|

Normal Working Temperature |

50°C~70°C |

50°C~70°C |

50°C~70°C |

50°C~70°C |

50°C~70°C |

50°C~70°C |

50°C~70°C |

|

Concrete Mixer Truck Customization

Mixer Truck composed with chassis, power system, hydraulically system, water system, sidebar, dram, board, operation system, body subframe, discharging part, and concrete chute.

Main structures of DTA mixer:

• Adopt combined design of main and auxiliary cases.

• Adopt double H type operating mechanism

• Equip front-full PTO and side PTO

• Install clutch housing or release devices Cabin: with three seats and one sleeper, air-condition, radio, color optional

Mixer cubage: 9CBM

Mixer material: 16# Mn steel

Mixer thickness: 5-6mm

Speed of turning: 0-14r/min

Slump constant: 70-260mm

Slant angle: 15°

Rest of concrete: <=2%

Hydraulic pump brand: Italy ARk/USA Eaton

Hydraulic engine: Italy ARK/USA Eaton

Reducer: Italy TOP/Italy Bonfiglio

Radiator: Germany AKG

3-16CBM concrete mixer trucks with various engine horsepower or chassis are available.